Gluten Free Home Brewing Blog

Assessment of Water Absorption Across Various Gluten-Free Grains

Introduction:

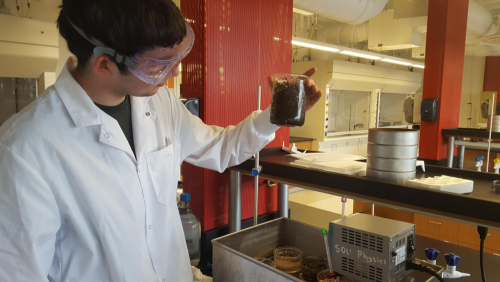

This research was carried out by Ben Barnes, undergraduate senior chemistry student at Southern Oregon University, on behalf of Gluten Free Home Brewing. The purpose of this research is to determine volume of water absorbed by various gluten-free grains during the Single Infusion Mash procedure (link included at end of report).

Experimental procedure:

A water bath with an initial temperature of 71.1 °C (160 °F) was prepared. In this experiment, there were eight total samples: two millet, two buckwheat, two naked rice, and two rice samples (each grain sample contained 15% rice hulls except the rice sample which naturally contains 37.5% rice hulls). For each grain sample, 350 mL (0.370 quarts) of unfiltered tap water was deposited in a 600 mL beaker. The beakers were then placed in the water bath, and the water within the beakers was allowed to equilibrate to the water bath temperature. Then the beakers were removed one at a time from the water bath and 134.3 gram (0.296 pound) samples of the grains were added to their corresponding beakers. These grain samples were pushed into the water within the beakers.

After the grain additions, beakers were returned to the water bath and allowed to steep, with periodic temperature measurements of the contents of each beaker. After 120 minutes, all samples were removed from the water bath and water was separated from the grain by two methods.

The first method (method A) involved pouring the contents of the sample beaker into a funnel lined with a mesh bag. The water that flowed through the mesh filter was discarded, and the saturated grain was collected from the funnel and placed in a pre-weighed beaker. The saturated grain was then weighed by difference. This method was performed on one of the millet, buckwheat, naked rice, and rice samples.

The second method (method B) was performed on the remaining four grain samples. This method involved draping a single layer of the mesh bag over the top of a beaker containing saturated grain that had been placed in the water bath. The beaker was inverted, and the water was allowed to flow through the mesh. Once water stopped flowing, the beaker was again placed right side up, and the saturated grain was weighed by difference in the same beaker to reduce grain lost during transfer.

Results:

Once grain samples were added to the beakers, water-grain mixture temperatures dropped to roughly 65 °C (149 °F). The target temperature range was 68.3 °C – 73.9 °C (155 °F-165 °C). After 30 minutes of continuous heating in the water bath, samples were removed one at a time periodically and temperature was recorded at 15 minute increments. The recorded temperatures are reported below in table 1. For some amount of time between 15 and 30 minutes at the beginning of the heating, the beaker temperatures were below the target range by at least 3 °C and 6 °F.

Table 1. Temperatures of grain samples at various times over the course of 120 minute heating. Note: one grain sample was spot checked at 15 minutes, and was 65 °C.

|

Time (min) |

30 |

40 |

55 |

70 |

85 |

100 |

|

Millet A (°C) |

69 |

69 |

71 |

71 |

70 |

70 |

|

Millet B (°C) |

74 |

70 |

70 |

71 |

69 |

|

|

Buckwheat A (°C) |

74 |

73 |

73 |

71 |

71 |

71 |

|

Buckwheat B (°C) |

74 |

74 |

73 |

72 |

70 |

|

|

Naked Rice A (°C) |

70 |

72 |

74 |

73 |

71 |

71 |

|

Naked Rice B (°C) |

75 |

74 |

74 |

71 |

71 |

|

|

Rice A (°C) |

69 |

72 |

74 |

72 |

71 |

70 |

|

Rice B (°C) |

73 |

72 |

72 |

70 |

70 |

Calculations involved measuring change in mass between the dry grain and wet grain after the water bath step of the procedure. Then, assuming that the change in mass resulted from water absorption, the mass of water absorbed was converted to volume of water absorbed using a water density of 1.00 g/mL. This volume of water, divided by the initial mass of dry grain, yielded the volume of water absorbed per mass of grain.

Table 2 shows the volume of water absorbed by mass of the four grains, as determined by method A and method B. Method A uncertainty was calculated under the assumption of 3 gram uncertainty in grain mass, and method B uncertainty was calculated under the assumption of 2 gram uncertainty in grain mass.

Table 2. Volume of water absorbed by grain samples per mass/weight of grain, given in quarts per pound and milliliter per quart.

|

Grain sample |

Volume of water absorbed by grain per unit weight of grain (quart/pound) |

Volume of water absorbed by grain per mass of grain (mL/g) |

|

Millet A (°C) |

0.52 ± 0.01 |

1.08 ± 0.02 |

|

Buckwheat A (°C) |

0.96 ± 0.01 |

2.00 ± 0.02 |

|

Naked Rice A (°C) |

0.93 ± 0.01 |

1.94 ± 0.02 |

|

Rice A (°C) |

0.78 ± 0.01 |

1.63 ± 0.02 |

|

|

||

|

Millet B (°C) |

0.645 ± 0.008 |

1.35 ± 0.02 |

|

Buckwheat B (°C) |

0.992 ± 0.008 |

2.07 ± 0.02 |

|

Naked Rice B (°C) |

0.937 ± 0.008 |

1.96 ± 0.02 |

|

Rice B (°C) |

0.828 ± 0.008 |

1.73 ± 0.02 |

It was observed that by both method A and B, buckwheat absorbed all of the water in the beaker, with nothing left to filter out. When filtered, naked rice yielded only a few drops of water.

Discussion:

In this experiment, the extent to which four types of grain absorb water under Single Infusion Mash conditions was evaluated by two methods. In practice, method A resulted in greater loss of grain while transferring to the mesh-lined funnel, as well as additional loss of grain stuck to the sides of the beakers. Method B approximated Single Infusion Mash conditions more accurately, as no grain mass was lost during transfer, and there was no water unnecessarily squeezed from the wet grain during transfer between beakers. Therefore, the water absorptions determined by method B was more reliable than that determined by method A.

In these experiments, one source of error stemmed from loss of grain during weighing. A liberal estimate of lost grain mass in method B would be 2 grams, and the resultant uncertainties calculated from this assumption are shown in table 2. Another potential source of error stemmed from the lack of mesh grain bags in each individual beaker during heating. The lack of a bag containing the grain may have resulted in more loosely-packed grain that absorbed a greater amount of water than would have been allowed with a bag. If this is the case, the result would be artificially high absorbance rates.

Another potential source of error stemmed from a low initial water bath temperature (strike temperature). Although the initial water bath temperature was within the range allowed by the procedure, adding the grain lowered the water temperature below the allowable range for between 15 and 30 minutes. This error would be expected to lower the amount of water absorbed by the grain. However, the higher than expected grain absorbance rates suggest that this low strike temperature did not adversely affect results.

As stated in the results, buckwheat samples appeared to absorb all of the water in the beakers, and naked rice absorbed nearly all of the water. These grains would have absorbed more water if the beaker had contained more water, and their reported water absorbance rates are low. The water to grain ratio was 1.25 quarts to 1 pound, which was the greatest amount of water allowed by the Single Infusion Mash procedure. These results show that buckwheat and naked rice absorb significantly more water than traditional grains.

To better determine the water absorbance of buckwheat and naked rice, future research could replicate the procedure of this experiment but increase the water to grain ratio so that more water could be absorbed. Another possible modification of this experiment would be scaling up the volumes and masses so that each individual grain sample could be encased in a mesh bag to more closely replicate Single Infusion Mash procedure.

Link to Single Infusion Mash procedure: https://www.glutenfreehomebrewing.com/all_grain_brewing_tutorial.php