Gluten Free Home Brewing Blog

Introduction To Ondea Pro Liquid Enzyme Complex

By Jason Yerger, owner and head brewer at Mutantis Brewery & Bottle Shop

and JP Bierly, owner and head brewer at Bierly Brewing Company

There's a new enzyme in town, and it's a real game-changer for the gluten-free homebrewing community! As many of you intrepid homebrewers probably know by now, even when gluten-free grains are malted, they don't develop the same amount of enzymes that are found in malted barley, and they can't usually be mashed successfully without enzyme supplementation. However, the only enzymes that have been available to homebrewers have typically been amylase enzymes—mostly alpha-amylases, but occasionally glucoamylases. These enzymes do facilitate the conversion of some types of starch into sugars, but other types of starch resist their activity, and some grains have other components that inhibit conversion as well, like proteins and lipids. This means that a lot of the time, gluten-free brewers are not able to get complete extraction and conversion in their mashes, resulting in lower brewhouse efficiencies and lower attenuation compared to what barley brewers are accustomed to. Ondea Pro finally provides some crucial missing enzymes that will significantly improve gluten-free mash processes.

A unique preparation from Novozymes, the makers of Termamyl, Ondea Pro was originally designed to be used with a mash of 100% unmalted barley. It contains a variety of enzymes not previously available to homebrewers: lipase, protease, cellulase, and pullulanase (and also a non-heat-stable form of alpha-amylase, though enzymes of that type are already widely available). It is designed to be used with a step mash to allow each enzyme a window to work in its optimal range. It is also recommended to pair with a heat-stable alpha-amylase to get the best conversion during the higher-temperature steps in the mash. Several brewers, both homebrewers and commercial brewers, have been conducting independent experiments with Ondea Pro, and have found the results to be extremely encouraging. Beers made with Ondea Pro show much higher mash efficiencies, better body and head retention, and more controllable attenuation compared to all other kinds of mashes that rely entirely on amylase enzymes.

In this blog entry, we're going to give an overview of how Ondea Pro works, report on the results of some of our trials, and provide an outline of some mash protocols to use with Ondea Pro. There is not yet a consensus on what the optimal time, temperature, pH, and dosage are, as there's still a lot of room for experimentation, but the initial results are so promising that it's well worth the trials!

Buy Ondea Pro Here!

Applications of Ondea Pro

The most important application of Ondea Pro is in working with rice malt. According to Jim Eckert, the rice variety he malts is composed of 80% amylopectin and 18% amylose on average. Amylopectin is a type of starch where the molecules contain numerous branches; amylose, by comparison, is a type of starch with no branches, being essentially a straight chain of carbohydrates. Amylase enzymes work by cleaving starch molecules at particular bonds, typically what are referred to as 1,4-glucosidic bonds. This is fine for amylose, as those kinds of bonds are the main type. But in amylopectin, the branches are formed with 1,6-glucosidic bonds, which alpha-amylase cannot break. Without something to break the 1,6-glucosidic bonds, beers made with rice malt suffer from both poor attenuation and low extraction efficiency, meaning a significant amount of starch remains unextracted and unconverted.

Glucoamylase, the enzyme commonly used in brewing brut IPAs, can break those bonds, but in doing so makes a lot of glucose and very few dextrins, resulting a beer with a thin body, little head retention, and a high degree of attenuation. This is great for certain styles, but is far from ideal when a full-bodied beer with excellent head retention is desired. Thankfully, there's another enzyme—pullulanase—that can break the 1,6-glucosidic bonds, but primarily producing dextrins rather than glucose. Alpha-amylase can then break those dextrins down further into maltose, maltotriose, and other more complex carbohydrates. This is where Ondea Pro comes in: because it contains pullulanase, as well as other enzymes like lipase, cellulase, and protease, it gives brewers the ability to unlock the full potential of rice malt!

To put it in practical terms, using Ondea Pro with malted rice not only allows for better attenuation without stripping body the way a glucoamylase mash does, it also allows more sugars to be extracted in general. Malted rice has long been treated as having lower extract potential than millet malt, with roughly 20 PPG estimated for pale rice malt. But with Ondea Pro, we've discovered that rice malt is actually very, very close to millet malt in extract potential. Early trials produced mash efficiencies well in excess of 100% based on a 20 PPG estimate for malted rice; one trial went as high as 140% efficiency in a partial-mash beer. Even with a corrected extract potential of 26 PPG being used, trials have been in range of 85% to 104% efficient, with attenuations ranging from 68% to 88% depending on the mash steps and enzyme dosages used. As a result, we can now recommend that rice malt be considered to have an extract potential of at least 27 PPG, and possibly as much as 30 PPG.

As an added bonus, our trials also suggest that mashing with Ondea Pro actually improves the flavor of beers made with rice malt, especially those that are very high in rice malt. Many brewers have noted that beers high in rice malt have a characteristic off-flavor, described variously as "celery seed", "wintergreen", "smokey", or "phenolic", regardless of the type of rice malt used. In one trial, we brewed an all-grain pale lager with 100% rice malt and found no trace of this characteristic flavor.

What about other malts, though? So far we have found that Ondea Pro may give a slight improvement to extraction of fermentable sugars from millet and buckwheat malts, but we do not have enough data to conclusively determine how much. At the very least, we are confident that we don't lose anything by using Ondea Pro compared to SEBAmyl L and SEBAmyl BAL 100. However, if you are not brewing with any rice malt, the benefit of using Ondea Pro instead of SEBAmyl L and SEBAmyl BAL-100 may not be significant.

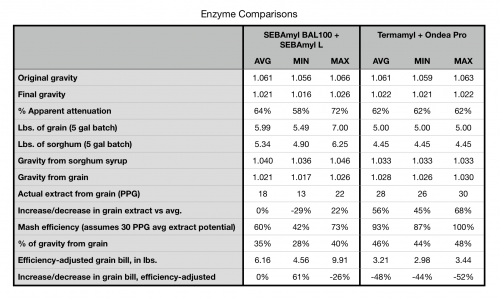

To get an idea of what homebrewers can expect when converting from a mash that uses SEBAmyl L and SEBAmyl BAL-100, to a mash that uses Ondea Pro, we have conducted trials at Bierly Brewing using a known recipe--Bierly's Baker Street Porter, which is based on the Roca Creek Porter recipe kit available on this site. This recipe is a partial-mash beer with close to equal parts millet malt and rice malt in the grain bill, so it should be a good middle ground to establish a baseline. Bierly Brewing has been brewing Baker Street Porter for over a year using a single-infusion mash at 163°F with a combination of SEBAmyl L and SEBAmyl BAL-100, so there is a large data set establishing a basis for comparison. We have so far conducted two trials using Ondea Pro and Termamyl with a rising-temperature two-step mash as described below. To get an accurate comparison across the whole data set, we standardized all measurements to the same batch size (5 gallons). You can see the results in the table below:

In the table, you can see that on average, both types of mash produced the same original and final gravities, but Ondea Pro increased the mash efficiency from 60% to 93%, allowed for a reduction in both grain bill size and sorghum syrup, and increased the amount of gravity derived from the grain relative to the gravity derived from the sorghum syrup. The "efficiency-adjusted grain bill" row shows what the size of the grain bill would be to match the average actual extract given the different efficiencies of the mash; for example, to get the average 18 PPG of actual extract using Ondea Pro, you would only need 3.21 lbs of grain, compared to the average of 6.16 lbs of grain when using SEBAmyl BAL 100 with SEBAmyl L in a single-infusion 163°F mash. That is a SUBSTANTIAL decrease in the amount of grain, and thus the cost of the recipe!

Using Ondea Pro

As mentioned above, there is not yet a consensus on the optimum way to use Ondea Pro, but brewers have seen good results with both rising-temperature step-mashes, and falling-temperature step mashes. A good starting point for experimentation would be the following mash:

Rising Temperature Step Mash:

Enzyme Dosage: 1 to 1.75 mL Ondea Pro per lb of grain; 1 mL Termamyl per lb of grain

Brewing water: 1.2 to 1.4 quarts per lb, non-chlorinated or RO water

Water salts: add enough Magnesium Sulfate (Epsom salt) and Calcium Chloride to achieve at least 10 ppm Magnesium, 10 to 50 ppm Calcium, and a 1:1 to 6:1 ratio of Sulfate to Chloride

Mash pH: 5.0 to 5.5

Step 0 (optional): Pre-cook only the malted rice portion of your grain bill by mixing with water at or close to boiling temperature, using a liquor to grist ratio of 1 to 1.5 quarts per lb. Rest for 15 minutes, then proceed to Step 1. This step provides a slight increase in mash efficiency, but is not required for a successful mash.

Step 1: Dough in for a first rest at 140°F; if pre-cooking the rice, you will need to adjust your strike water temperature downward to correct for the temperature of the cooked rice. Add mash water salts, lactic acid if necessary to adjust pH into proper range, and both enzymes. Rest for 45 to 60 minutes. This is near the optimal temperature for pullulanase, protease, lipase, and cellulase, so you can think of this step as preparing the starches in the mash to be broken down by the amylase enzymes in the next step.

Step 2: Gently raise mash temperature to 180°F over 30 to 45 minutes, then hold at 180°F for 30 to 60 minutes. You can vorlauf during this step if you have a recirculating mash setup. The reason this step is at such a high temperature is because Termamyl's activity actually peaks near the boiling point of water, so the higher temperature increases its activity while also ensuring all of the starches are fully gelatinized. The high temperature also makes sparging easier because it makes the wort less viscous.

Step 3: Sparge and lauter as normal.

If you do not have the capability to raise and maintain mash temperature (i.e. if you are mashing in a cooler and don't have a HERMS or RIMS setup), you can also try a falling-temperature step mash, which will be a little more complicated in terms of enzyme additions since you can't add the Ondea Pro in the first step. This mash may also produce a less fermentable beer; we have conflicting data on that. Follow these instructions instead if you want to try this method:

Falling Temperature Step Mash:

Enzyme Dosage: 1 to 1.75 mL Ondea Pro per lb of grain; 1 mL Termamyl per lb of grain

Brewing water: 1.2 to 1.4 quarts per lb, non-chlorinated or RO water

Water salts: add enough Magnesium Sulfate (Epsom salt) and Calcium Chloride to achieve at least 10 ppm Magnesium, 10 to 50 ppm Calcium, and a 1:1 to 6:1 ratio of Sulfate to Chloride

Mash pH: 5.0 to 5.5

Step 1: Dough in for a first rest at 185°F. Add Termamyl only, as well as mash water salts; do not adjust pH. Rest for 45 to 60 minutes allowing temperature to fall naturally. The Termamyl should be quite active during this step, but don't expect to pass an iodine test at the end of it.

Step 2: Once temperature has dropped below 155°F, add Ondea Pro. Stir thoroughly for at least 5 minutes. Rest for 45 to 60 minutes. You can vorlauf during this step if you have a recirculating mash setup. Note: we have conflicting data regarding the effects of pH alteration on this step, and it may actually be detrimental to reduce the pH here, even though in theory a lower pH should be more optimal; based on trial results we are not currently recommending reducing pH when using this falling temperature mash.

Step 3: Sparge and lauter as normal.

Controlling Attenuation

One of the main issues encountered during testing of Ondea Pro has been under-attenuation, resulting in higher finishing gravities than other mash methods. This can be desirable for some styles of beer, where a full body with lots of residual sweetness is appropriate, but if you wish for a dry finish and a lighter body, that can likely be achieved in a couple of different ways. Some trials have suggested higher dosages of Ondea Pro (1.5 to 1.75 mL per pound of grain, or more) and a longer rest at 140°F make a more fermentable wort. It's also possible that an intermediate rest at 155°F, with the addition of an extra amylase, may increase fermentability as well.

However, the most surefire way to increase fermentability is by using a glucoamylase, such as AMG-300, on the wort collected from the mash, prior to boiling. Glucoamylases are generally not very heat-stable, and will deactivate rapidly above 150°F in most cases. So once you have a kettle full of wort, you can increase the fermentability by adding varying amounts of glucoamylase and resting for shorter or longer lengths of time before turning up the heat and deactivating the enzyme. As with Termamyl, around 1 mL per lb of grain that you mashed is a reasonable starting dose for glucoamylase; rest anywhere between 10 and 30 minutes, or up to 60 minutes if you want an extremely-fermentable beer.

Another surefire solution is to simply remove some of your pale malts, and replace their gravity contribution with sugar or some other source of glucose, dextrose, and/or sucrose. According to the Oxford Companion to Beer, a typical all-malt wort in barley brewing would be "12% monosaccharides, 5% sucrose, 47% maltose, 15% maltotriose, and 25% higher saccharides, such as dextrins." We hypothesize that the typical Ondea Pro mash skews more toward maltotriose and higher saccharide production, so reducing your malt bill by 5% to around 17% and replacing with sugar should achieve higher attenuation, with minimal impact on flavor and body—but a positive impact on your wallet!

If for some reason you encounter overattenuation with the normal Ondea Pro mash, you can reduce the fermentability of the wort by shortening the length of the low-temperature mash rest, slightly raising the temperature of that rest by a few degrees, or reducing the enzyme dosage.

Conclusion

We still have a ways to go in figuring out the optimal mash for gluten-free grains. However, with the massive boost in extraction efficiency we've seen with Ondea Pro in a two-step rising temperature mash, we felt it was important to make this powerful new tool available to the homebrewing community. Intrepid homebrewers can now work alongside the growing number of commercial gluten-free breweries conducting research on how to best use this enzyme in making higher-quality gluten-free beer than we previously thought possible!

In a future blog post, we are going to cover the results of some all-grain trials with a standardized grain bill, comparing the Ondea Pro mash with a variety of mash profiles that use only the SEBAmyl L and SEBAmyl BAL-100 enzymes, to give a more conclusive demonstration of how enzymes and temperature steps impact efficiency and attenuation. Stay tuned!

Buy Ondea Pro Here!

Watch us pour our first beer brewed using Ondea Pro

Follow our blog and newsletter for updates about brewing using Ondea Pro.

Cheers!